Steel Temper Colors: Temperatures & Explained

July 8, 2022 | Categorized in: Properties

We’ve discussed the primary ways of heat treating steel before, but it’s worth going into more detail for some of them, such as tempering. Not only is it a common and effective method for enhancing your steel, but it also makes the most obvious visual difference. Before we get to those visual differences, we need to understand the basics of what the tempering process involves.

What is tempering?

Tempering is a method of heat treatment usually performed after quenching, where the steel is reheated to a precise temperature below the lower critical temperature and holding (or soaking) it there. Heating above that critical temperature is avoided because it will destroy the strong microstructure from quenching, called martensite. After a set time at the given temperature, the steel is allowed to slowly cool back to room temperature.

Like all forms of heat treating, this done is to alter the physical and chemical properties of the metal, often to increase its strength. In this instance, tempering is used to reduce the brittleness and hardness and thereby increase the ductility and toughness.

Types of steel tempering

There are also different variations of tempering that are tailored for specific results. The primary methods of tempering are:

- Differential tempering – also called selective or graded tempering, this process tempers selective parts of a piece of steel (or at different temperatures) and is commonly used for tools or blades that need a hard edge but some malleability in the rest of the tool.

- Austempering – this process is used to form bainite, a specific microstructure, and heats the steel more than other tempering techniques.

- Martempering – similar to austempering, this method forms martensite instead of bainite by quenching at a much lower temperature.

- Black tempering – this results in black iron and is done in the presence of inert gasses with very high temperatures and for long periods of time (at least 20 hours).

- White tempering – taking black tempering even further, this method uses even hotter temperatures for nearly 60 hours, cooled at a slower but specific rate, and results in malleable or porous cast iron.

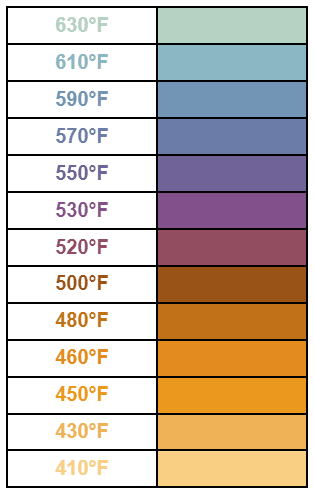

Steel temper color chart

Depending on the temperature that the steel is held at during tempering, the metal actually changes its color. Lower tempering temperatures primarily relieve internal stresses and slightly lower the brittleness, while higher temperatures (up to the critical temperature) result in larger decreases in brittleness. This sacrifices yield and tensile strength for improved elasticity and plasticity. The full chart of tempering colors is below:

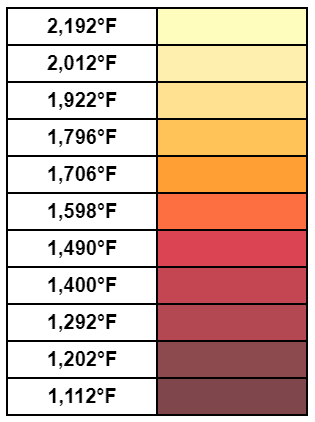

Steel forging color chart

Tempering colors are different from the colors that heating steel for forging (or other forms of heat treating) causes. These are always shades of red, orange, and yellow because they’re above the critical (or transformation) temperature that makes the metal glow from the heat. Forging colors are as follows:

What causes the change in color?

When a piece of steel is tempered, a thin oxide layer forms on the surface of the metal. As the temperature increases, the steel oxidizes more easily and deeper. Depending on the depth of this layer, specific wavelengths are enhanced and reflected, while others are absorbed. What we see is the reflected wavelengths, which changes the color based on the thickness of the oxidation, and the temperature that caused it.

Get strong steel for your projects today

No matter what structural steel products or services you need, from galvanizing to impact testing, Service Steel has you covered. Our massive inventory is ready to ship so you can get what you need even quicker.

Request a free quote for your steel today