T-Beam Basics: Types, Usage, & Size Guide

June 12, 2024 | Categorized in: Types

In the world of structural engineering and construction, T-beams play an important role in providing strength and support to a variety of structures. With their distinctive T-shaped cross-section, these versatile beams are crucial for supporting heavy loads over wide spans (making them a preferred choice in many construction projects).

In this blog post, we’ll cover the basics of T-beams: how they’re made, where they’re used, their unique properties, as well as how to understand their sizing and dimensions. Whether you’re a seasoned professional or just beginning to explore the world of structural design, this guide aims to provide valuable insights into the fundamentals of T-beams and their significance in building strong and resilient structures.

What is a tee beam?

A tee beam, also known as a T-beam, is a type of structural beam that resembles the letter “T”. The horizontal top part of the “T” is referred to as the flange and the vertical stem is called the web. The horizontal flanges resist bending, while the vertical web provides shear resistance. Because of their “T” shape, this type of steel beam is most often used to support loads over a span, allowing for efficient distribution of loads to prevent sagging or failure.

Tee beams vs. wide flange beams and I-beams

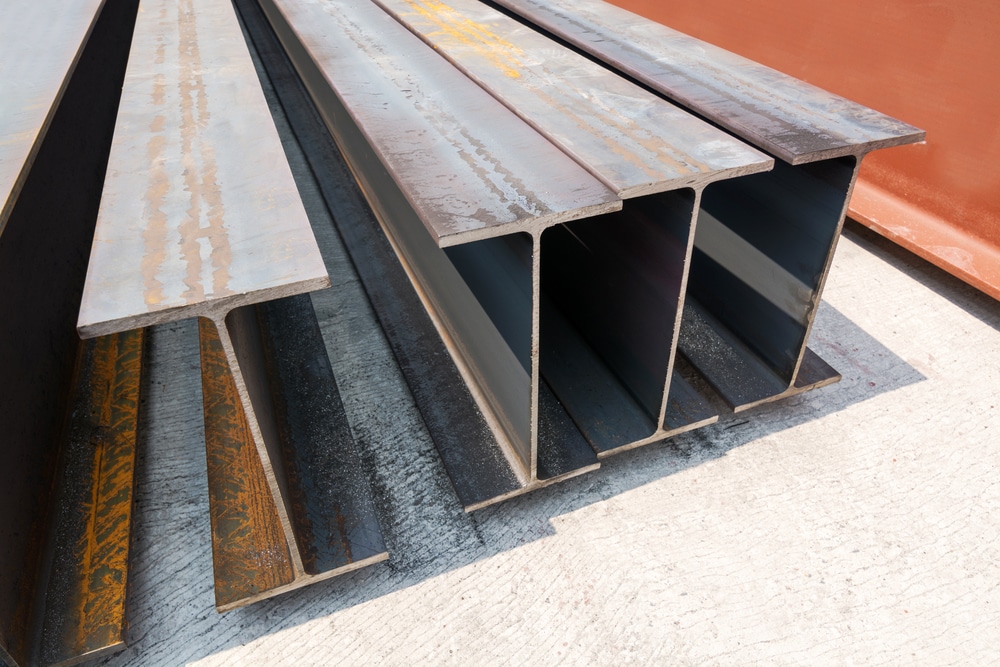

Steel T-beams (left) vs. wide flange beams (right)

While both tee beams and wide flange beams are structural elements used in construction, they differ in their shape, as well as how they are used. They can be split from wide flange beams and the T-beam resembles the letter “T”. This design provides efficient resistance to bending forces and is often used in scenarios where longer spans are required, such as in bridges or multi-story buildings.

On the other hand, wide flange beams often resemble the capital letter, “H”. This shape beam features wider flanges at the top and bottom which are connected by a narrower web to distribute the weight better across a large area. Similar to wide-flange beams, I-beams resemble an “I” or “H” shape, but with narrower flanges.

While T-beams are best used for specific span requirements, wide flange beams are used in a broader range of scenarios where extra strength is necessary. Learn more about purchasing steel beams or our tee splitting services today.

How are T-beams created?

T-beam steel can be created using a variety of methods such as hot rolling or welding. At Service Steel, we utilize a plasma track torch that’s specifically engineered for splitting the web of a wide flanged beam which results in two steel tees. Typically, these cuts are performed along the vertical web of wide flanged beams, but adjustments can be made to the cut-off center as per project requirements.

Applications of steel T-beams

Steel T-beams find applications in various structural scenarios due to their ability to achieve specific structural shapes as well as efficiently support heavy loads over spans. The specific application of tee beams depends on the engineering requirements of the project as well as the span length, load conditions, and other unique structural considerations.

That being said, here are a few examples of the most common construction and infrastructure applications for these types of steel beams:

- Bridges

- Building frames

- Parking garages

- Shipbuilding

- Floor structures

- Roof trusses

- Elevated structures

T-beam advantages

Steel T-beams and their unique “T” shape offer several advantages that make them a popular choice in various construction and structural applications:

- Cost-effective

- Higher load-bearing capacity

- Increased durability

- Easier to produce

- Longer span capability

- Versatile and customizable

Understanding T-beam sizes

Understanding these T-beam sizing specifications is essential for selecting the appropriate dimensions for a given structural application. Oftentimes, steel beam dimensions are written with the format WT 6 x 20 x 30 which might seem confusing at first, but it’s quite simple once you understand the formatting:

- “WT” stands for wide flange tee. In other instances, the letter before the measurement stands for different shapes. For example, “W” means a wide flange beam whereas “S” is for a Standard American I-beam.

- “6” represents the height of the beam in inches. This number is sometimes referred to as the “section number”.

- “20” represents the pounds per lineal foot, or how much each foot of the beam weighs.

- “30” as the final measurement represents the total length of the T-beam in feet.

To put it all together, this T-beam size, WT 6 x 20 x 30, is 6 inches tall, weighs 20 pounds per foot, and is 30 feet long — so in total it weighs 600 pounds.

At Service Steel, we offer structural tee beams in a full range of sizes from 5’ to 60’ in 5’ increments, in even quantities. If you’re interested in how much steel tee beams for your project would cost, reach out to us for a free custom quote!

Service Steel for your tee splitting needs

At Service Steel Warehouse, we pride ourselves on providing a comprehensive selection of T-beams, readily available for shipping in various sizes and lengths to cater to the unique needs of your projects. Whether you require specific types, sizes, or customized specs for your steel beams, our extensive inventory ensures that we can meet your needs.

If you have questions about T-beams and their dimensions or are interested in pricing details, reach out to us by phone or request a quote today! Additionally, take advantage of our full-service steel processing capabilities. From cambering to tee splitting, we can do it all!