History of Steel in Skyscrapers & High-Rise Construction

June 12, 2024 | Categorized in: History

In the constantly evolving skyline of our cities, towering steel high-rises stand as a testament to human ambition, ingenuity, and the pursuit of reaching new heights (literally and metaphorically). The journey of high-rise construction and its integration with steel, as we know it today, evolved over centuries. However, the technological leaps that brought them into existence are often overlooked.

In this guide, we will cover the fascinating history of steel in high-rise construction, along with how this metal has not only helped, but also accelerated the creation of these giants. You’ll learn more about the most iconic and impressive steel buildings and how they were built harnessing the strength of steel. All this to help you better appreciate the challenges, triumphs, and progress of steel architecture.

Early beginnings of high-rise construction before steel

The ambition to build tall structures and reach great heights is not unique to the modern era. In ancient times, long before the invention of steel, civilizations faced many challenges in their quest to construct tall buildings. Yet, despite the lack of materials and techniques that we know and use today, early architects and builders still managed to leave their mark on history.

- The Great Pyramid of Giza is one of mankind’s earliest “high-rises”.

One of the earliest examples of pre-industrial high-rise construction is Egypt’s Great Pyramid of Giza. Constructed in 2560 BCE, it still stands as the last of the original Seven Wonders of the Ancient World. Built using massive limestone and granite blocks, the Great Pyramid reached an awe-inspiring height of 481 feet. Its construction techniques, which included the use of a massive workforce and clever engineering solutions, set the stage for later civilizations to aspire to new heights.

While the pyramids of Egypt and similar ancient structures achieved remarkable heights for their time, the limitations from the materials (most often stone and brick) and techniques used were obvious. The ability to build higher in ancient times was greatly hindered by the reasons detailed below:

- Early building materials lacked the compressive strength needed to withstand immense pressure on lower levels.

- Pre-modern materials did not have the tensile strength required to withstand lateral forces and wind loads in tall structures, posing a risk of structural instability.

- The weight of traditional building materials, coupled with their lack of tensile strength, made constructing tall structures economically impractical and logistically challenging.

- Limited construction techniques and the absence of advanced machinery hindered the efficient building and support of tall structures in pre-steel times.

- Notably, inadequate foundation technology made it challenging to provide stable foundations for high-rising structures.

Thanks to the Industrial Revolution, this narrative would soon change, unlocking new possibilities and reshaping what can be achievable in high-rise construction.

The Industrial Revolution and evolving construction techniques

During the Industrial Revolution, improvements in iron production spurred many innovations.

The Industrial Revolution occurred from 1760 to 1840 and brought with it many significant advancements for high-rises, especially concerning construction and iron production. Mechanization became a cornerstone of this era, replacing manual labor with powered equipment. Emerging construction machinery powered by steam engines, including cranes, pile drivers, and excavators, enhanced the efficiency and scale of construction projects. With this era introducing standardized materials and pre-fabricated components like beams, standardization, and mass production became prevalent in construction.

When it came to advancements in these materials for building during the Industrial Revolution, trains played a pivotal role. The construction of railways created a huge demand for iron in railway tracks, bridges, and locomotives — and this demand contributed greatly to the improvement of iron production.

Innovations in smelting processes and the use of coke in blast furnaces increased the efficiency of iron production, making it a readily available and cost-effective material for construction. In turn, iron evolved from small decorative elements to large structural components, with iron beams, columns, and frameworks widely used in buildings and bridges.

Birth of skyscraper construction during the Steel Age

The Steel Age, also known as the Second Industrial Revolution, took place roughly between 1850 and 1920 and marked a shift in manufacturing and construction processes. During this time, the use of steel, which is far stronger and more versatile than iron, became more widespread. Steel provided architects, as well as engineers, with a reliable and durable building material that could withstand immense weight while offering more flexibility in design.

The Bessemer converter, invented in the 19th century by Sir Henry Bessemer, revolutionized steel production.

One of the most important moments for this time period came in the 1850s when the “Father of Steel”, Sir Henry Bessemer, developed the Bessemer process. The new method revolutionized high-rise construction even further by allowing the mass production of steel. Along with his invention of the Bessemer converter (pictured above), steel was now less expensive and more efficient to manufacture. This machine would blow air through molten iron to efficiently remove impurities, leading to high-quality steel, the perfect material for building skyscrapers.

By improving availability along with quality, steel became a game-changer for high-rise construction. At the same time, the strength and flexibility of steel allowed architects to design taller and more structurally ambitious buildings. Completed in 1885, The Home Insurance Building in Chicago is often regarded as the first skyscraper. This iconic high-rise utilized a steel skeleton structure, which demonstrated the possibility of constructing buildings to reach new heights.

This increased use of steel framing systems, combined with innovations like the elevator and improved foundation technologies, fueled the vertical expansion of urban buildings. In the following decades, skyscrapers would become and remain symbols of modernity and economic prosperity as they transformed the skylines of cities around the world.

Technological advancements for modern skyscraper construction

The Marina Bay Sands in Singapore showcases the strength and versatility of steel in modern-day skyscraper construction.

After the Steel Age and into the early years of the 21st century, the use of steel in high-rise construction continued to go through remarkable advancements. In the early to mid 20th century, structural steel framing was introduced and its use quickly became widespread. Additionally, with new and innovative welding techniques, steel connections were further strengthened. Together, this allowed for taller, more robust structures and the creation of increasingly complex and towering buildings.

As the 21st century progressed, incredible technological advancements for construction high-rises were made in four key areas:

- Introduction of CAD (computer-aided design) as well as advanced engineering software, which improved the precision of steel construction.

- Widespread utilization of high-strength steel alloys that provided structures with greater load-bearing capacities while maintaining a lightweight profile.

- Adoption of seismic-resistant technologies with advanced dampening systems and flexible steel frames allows skyscrapers to withstand strong lateral forces.

- Increased focus on sustainability and reducing the environmental impact of high-rise construction.

High-rise steel architecture trends across the decades

From the pioneering spirit of the early 1900s to the cutting-edge innovations of present day, each decade since the Industrial Revolution has left a mark on our favorite skylines. The evolution of incredible skyscrapers and architectural trends have slowly shaped the construction of steel high-rises year by year, decade by decade.

1880s-1920s: Early successes and the race for height

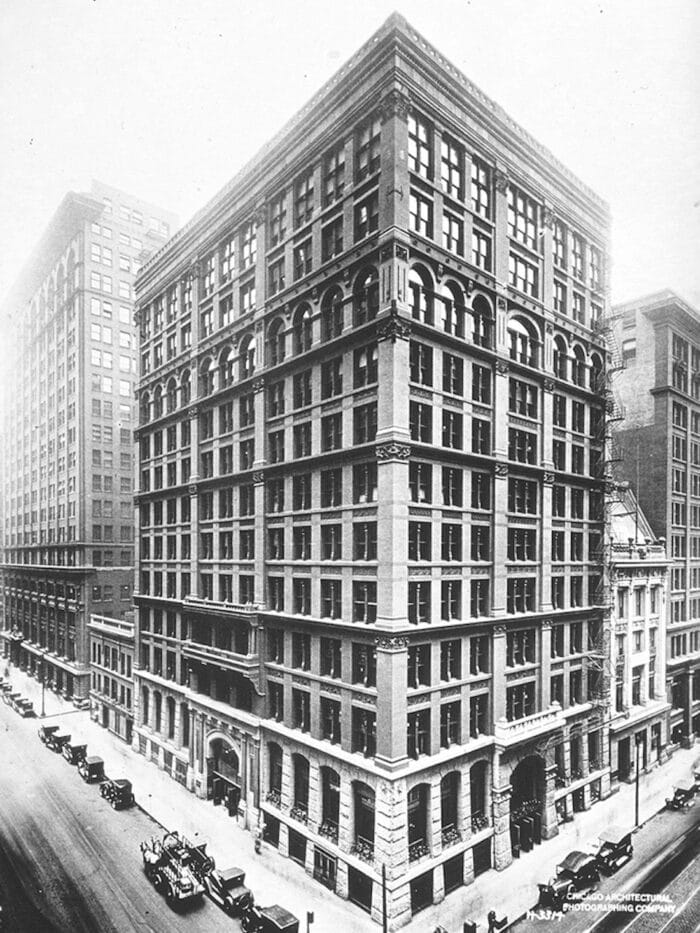

Credit: Chicago Architecture Center

This era marked a race for height supremacy with architects like Louis Sullivan pioneering steel-framed skyscrapers. Iconic structures like the Woolworth Building and the Chrysler Building built in this period demonstrated both engineering triumphs and aesthetic aspirations.

What was the first skyscraper in the world?

Designed by architect William Le Baron Jenney, and completed in 1885, The Home Insurance Building (pictured above) in Chicago, is considered the first steel-framed skyscraper. While it wasn’t tall by today’s standards, this high-rise stretched to 138 feet with 10 stories. Sadly, this historic building was demolished in 1931.

1930s-1950s: Art Deco and the Golden Age of Skyscrapers

Rockefeller Center in New York City

The Art Deco movement influenced designs, seen in landmarks like the Rockefeller Center (pictured above) and the Empire State Building. The 1950s introduced curtain wall construction, allowing more extensive use of glass in mid-century skyscrapers.

1960s-1980s: Innovations in design and steel construction methods

John Hancock Center in Chicago

The mid-20th century brought innovations like the tube structural system used in the John Hancock Center (pictured above) and Willis Tower, and steel modular structures like the World Trade Center. This is really when advances in construction materials and engineering techniques pushed skyscrapers to unprecedented heights.

1990s-2010s: Sustainability, new materials, and the race for the tallest

Petronas Towers in Kuala Lumpur, Malaysia

The late 20th and early 21st century has emphasized sustainability, as seen in the Petronas Towers (pictured above) and Taipei 101, and introduced new materials like high-strength concrete and advanced steel alloys. This era continues the race for the world’s tallest, symbolized by structures like the Burj Khalifa.

Future of steel frame construction for skyscrapers and high rises

It’s tricky to precisely predict the future of steel, but as the industry continues to evolve with research and development of new alloys and fabrication methods, it’s exciting to see what solutions are right on the horizon. Drawing from our extensive experience spanning decades of industry changes, we are predicting innovations and solutions such as:

- BIM (or Building Information Modeling) will streamline design and construction, enhance precision, and minimize errors.

- Robotics and automation will further improve project timelines and reduce costs with modular construction and prefabrication methods.

- Sustainability will be a top priority in minimizing the environmental impact of steel production and high-rise construction processes.

- An increase in the need for high rises that can withstand catastrophic events in which structural steel will play a crucial role.

As cities continue to grow vertically, redefining the skyline, they will set new standards for urban development. The future of high-rise construction will likely be spurred by a combination of cutting-edge technology, sustainable practices, and robust materials.

Some incredible examples of these trends in place include notable new high-rises in development such as the Green Spine in Melbourne, which will have a steel exoskeleton and an emphasis on green spaces and sustainability, and the Jeddah Tower in Saudi Arabia, built with a steel frame that will stand almost 600 feet taller than the Burj Khalifa.

High-quality steel, strong enough for building skyscrapers

The evolution of steel in high-rise construction has been a remarkable journey, shaping skylines and redefining architectural possibilities. From the groundbreaking innovations of the late 19th century to today’s cutting-edge technologies, steel remains the backbone of towering structures worldwide. At Service Steel Warehouse, we take pride in contributing to this legacy.

As one of the top steel suppliers, our commitment to providing high-quality steel ensures that architects and builders have the foundation they need for ambitious projects. With a diverse range of steel products and services, we strive to empower the construction industry, offering tailored solutions and unmatched expertise. The steel industry continues to evolve, which is why we are here to guide you through the ups and downs of the market with our tailored solutions and localized support. Future-proof your operations today by giving us a call or requesting a quote from our team today!